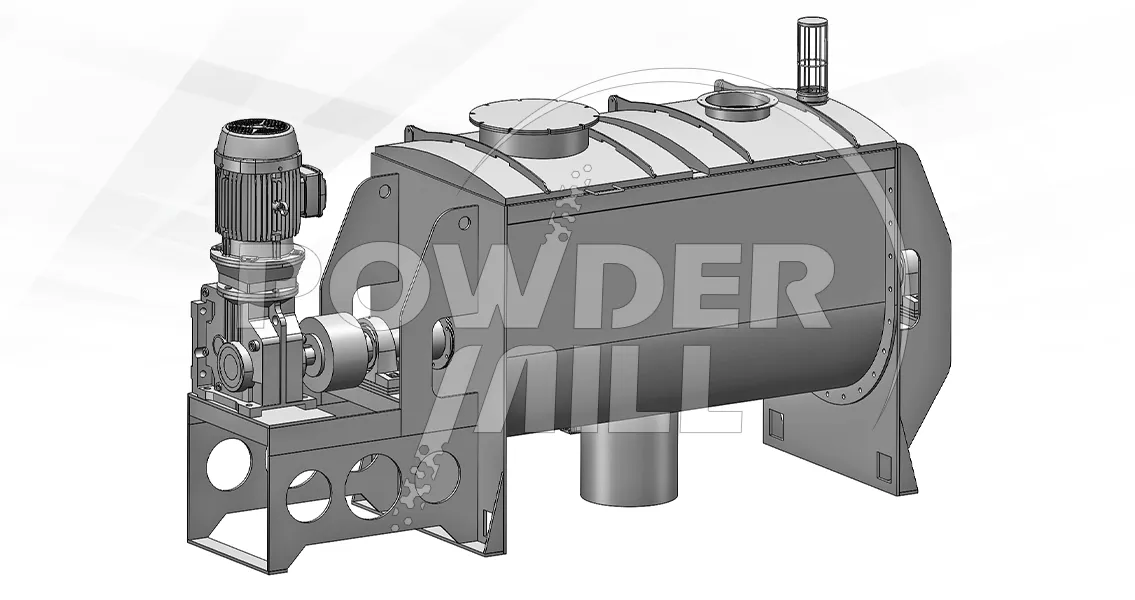

Poultry Feed Mixer Machine

The poultry feed mixer machine uses U-shaped barrel with double-layer spiral ribbon stirring blades to jointly build an efficient and uniform mixing system. The outer spiral ribbon is like a pair of skillful hands, guiding the material from both sides of the barrel to the center, while the inner spiral ribbon is responsible for dispersing the material from the center to both sides again. This convection mixing method ensures that the material is evenly mixed in a short time, significantly improving production efficiency.

Horizontal ribbon mixer is widely used in chemical, pharmaceutical, food, feed and other industries. Their unique design and powerful functions make them popular in the mixing field.

In order to meet the mixing needs of different materials, poultry feed mixing machine is also highly flexible. According to the characteristics of the material, auxiliary devices such as paddle stirring parts or flying knives can be added to further enhance the mixing effect. At the same time, the design of the barrel cover also fully considers the convenience of actual operation.

The arched barrel cover can bear pressure and is suitable for occasions where pressurized mixing is required; and the fully open barrel cover makes easy to clean and maintain the equipment.

In terms of discharging, the poultry feed mixer also performs well. The discharge form of the pneumatic flap valve ensures that the material can be discharged completely and without residue, ensuring the continuity and stability of the production process.

In addition, in order to meet more diverse production needs, the poultry feed mixing machine can also be customized, such as adding special functions such as heating, cooling, positive pressure, vacuum, etc., to adapt to the special requirements of different industries and materials.

Whether the mixing of powder and powder, granules and powder, or powder and a small amount of liquid, the poultry feed mixer can provide excellent solutions to meet various complex mixing process requirements.

Poultry Feed Mixing Machine Application: