Chilli Crushing Machine

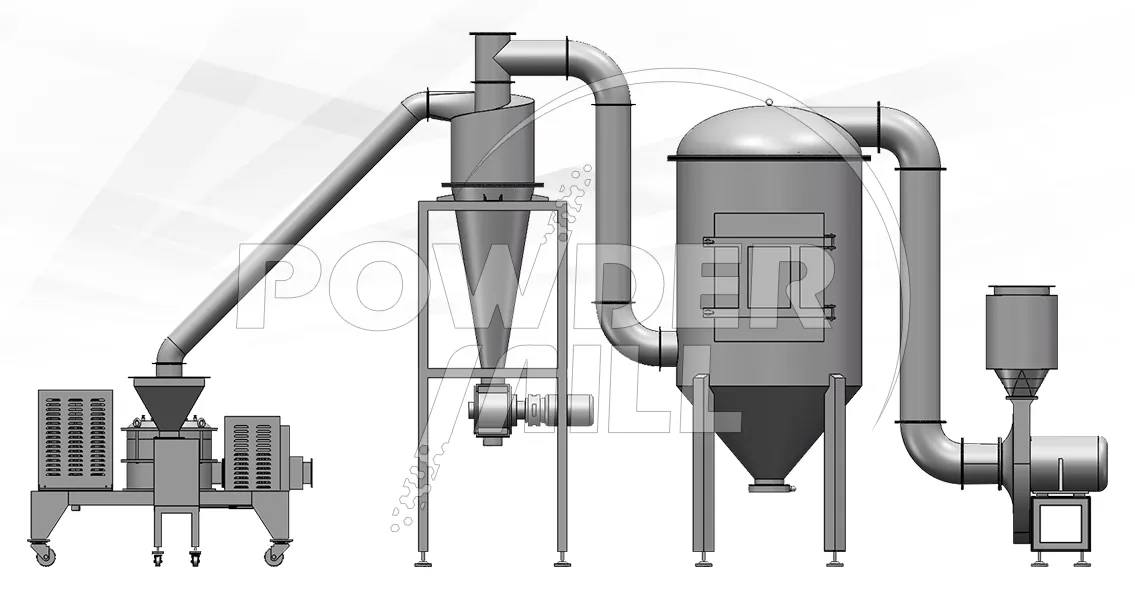

Chilli crushing machine uses ultrafine powder grinding machine, which is suitable for dried chili, black chili, spices, etc. The ultrafine grinder mainly consists of a feed hopper, a rotor, a toothed disc, a sieve, a housing, a base, a motor, and other parts.

Working Principle of Chilli Crushing Machine:

When the chilli crushing machine is in production, the motor drives the main shaft and the turbine to rotate at high speed. The turbine and the grinding block on the screen ring form a crushing and grinding pair, and its structure is compact.

When the chili enters the broyeur de poudre cavity from the feed hopper, the chili entering the machine cavity is closely rubbed and strongly impacted on the inner edge of the turbine blade in the rotating airflow, and is ground again in the gap between the blade and the grinding block.

While grinding the chili, the turbine inhales a large amount of air, which plays a role in cooling the machine, grinding the chili, and conveying the chili pieces. The fineness of the chili crushing depends on the size of the screen, as well as the amount of chili pieces and air passing through.

Precautions for Chilli Grinding Machine

1. The operator should stand on the side of the feeding port, and the hand is prohibited from reaching into the feeding port. The cover cannot be opened during operation and when the broyeur de piment is not stopped.

2. It is strictly forbidden to start the machine under load. When the feeding port is blocked, it is forbidden to force feed by hand or with a stick. Check immediately. Feed the material evenly and appropriately during operation. If there is semi-wet material, it is best to dry it in the sun or reduce the feeding amount.