Maintenance Method of Chili Grinder Machine

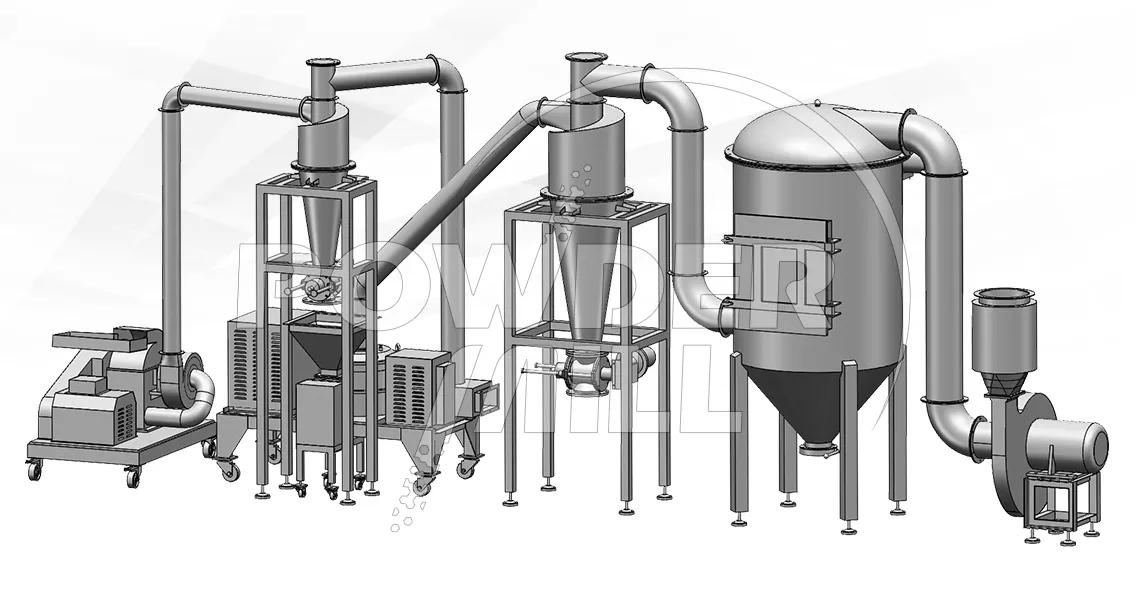

The chili grinder machine is composed of a cylindrical crushing chamber, a grinding wheel, a grinding rail, a fan, and a material collection system. The chili grinding machine is a device that uses air separation, heavy pressure grinding, and shearing to achieve ultrafine grinding of dry materials.

Maintenance Method of Chili Grinder Machine:

1. Frequently check the fastening of each part to prevent it from loosening and falling off and damaging the chili grinder.

2. The oil injection holes should be refueled frequently, and the bearing parts should be cleaned and filled with lithium-based grease every six months.

3. When the chili grinder stops working, it should be idling for a period of time, blow off the residual material inside the grinder machine, and then shut down.

4. When the grinder machine is out of service, the debris outside the machine should be removed, all rotating parts should be filled with grease; and stored in a warehouse with dry air and no corrosive gas.