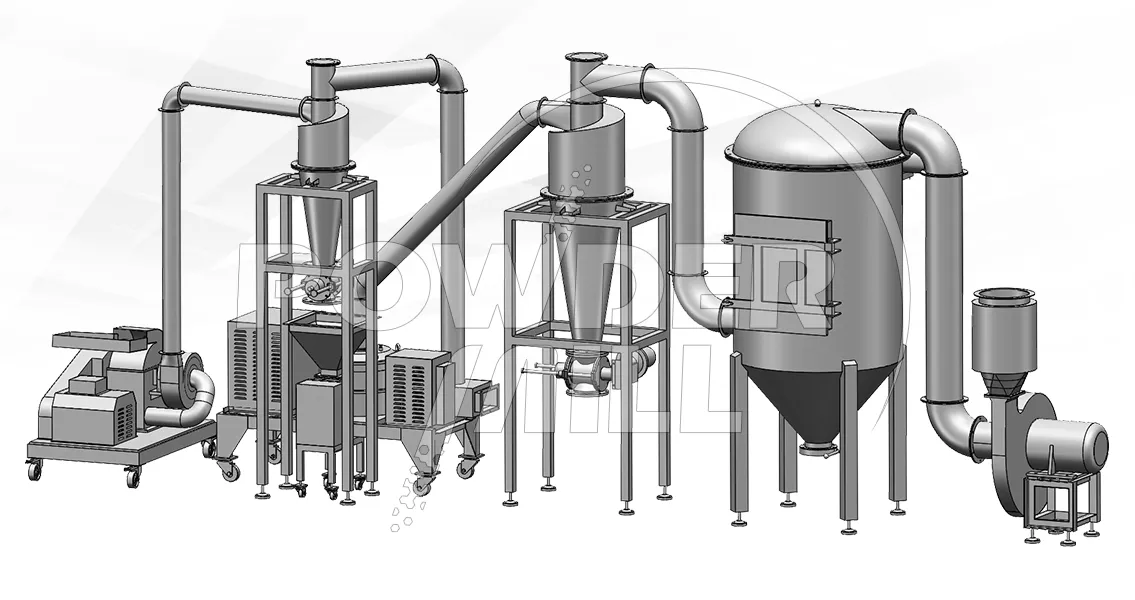

Moringa Leaf Powder Making Machine

The moringa leaf powder making machine is through the high-speed rotation of the crushing disc. Under the action of centrifugal force, the material is crushed by the impact of the hammer mounted on the crushing disc, and then is spun to the surrounding ring gear at a very high speed. The airflow between the ring gear and the ring gear is instantaneously alternated due to the change of the tooth surface. The material is subjected to alternating stress in this gap, and is further thoroughly crushed under this repeated action.

The powder making machine is made of medical stainless steel, which meets the requirements of GMP. The production process is fully enclosed, without dust, and without loss of materials. The powder processing machine is suitable for any fibrous, high toughness, high hardness or certain moisture content materials; for pollen or other spore plants that require breaking the cell wall, the wall breaking rate can reach 95%.

The crushing temperature is low, and the temperature of the powder produced will never exceed 50 degrees under the condition of continuous operation without cooling system. For customers with special requirements, a low-temperature system can be configured, and the lowest temperature can reach minus 35 degrees.

Technical Parameters:

| Model | Main Structural Dimensions(mm) | Capacity | Input Particle Size | Output Particle Size | Speed | Machine weight | Total power | ||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| L1 | L2 | H1 | H2 | H3 | H4 | W1 | Kg/H | mm | mesh | rpm | Kg | KW | |

| MR-350+20 | 5487 | 6810 | 859 | 2743 | 2862 | 650 | 1574 | 15-200 | 50 | 60-320 | 8600 | 1800 | 28.5 |

| MR-450+30 | 6370 | 7991 | 1056 | 3472 | 3352 | 650 | 1783 | 50-600 | 50 | 60-320 | 6700 | 3600 | 61 |

| MR-550+60 | 7288 | 9010 | 1096 | 3472 | 3652 | 800 | 2025 | 100-1000 | 50 | 60-320 | 5250 | 5300 | 106 |

| MR-550+80 | 8410 | 10372 | 1096 | 3472 | 4015 | 800 | 2199 | 120-1500 | 50 | 60-320 | 4850 | 7500 | 145 |

| Our company can be customized according to the user’s special requirements. | |||||||||||||