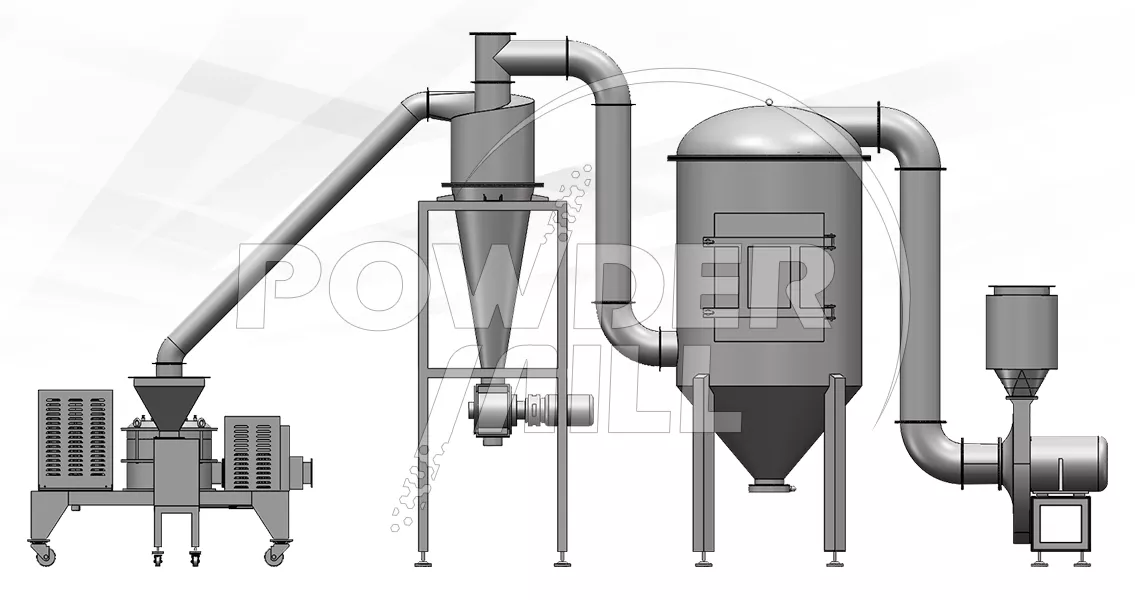

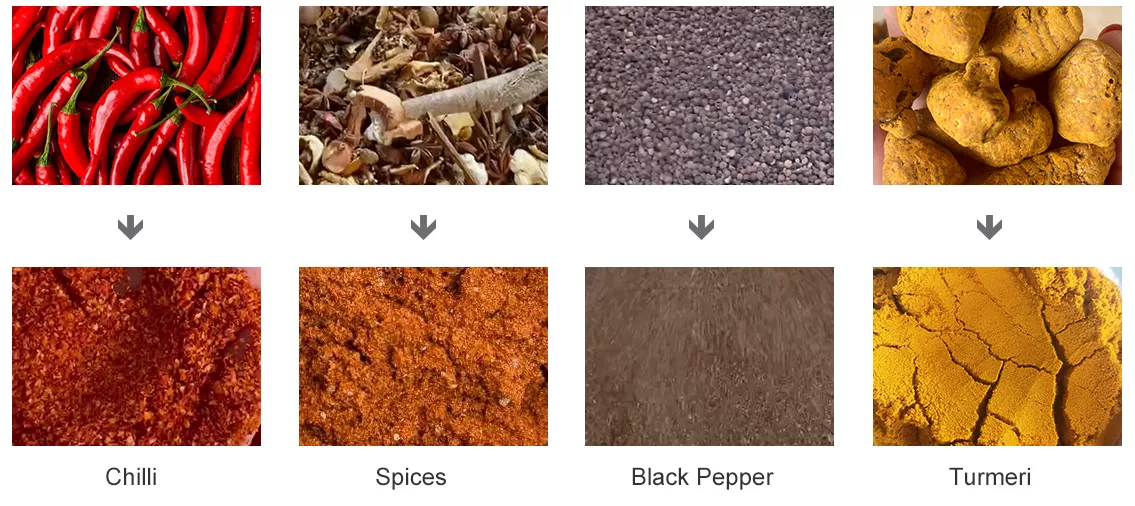

Powder Pulverizer Machine for Spices

Powder pulverizer machine has the characteristics of simple structure, firm, smooth operation, crushing material fast, uniform, good effect and so on. The pulverizer machine is made of stainless steel material, all the tooth slots inside the case (grinding groove) are machined by precision so as to achieve smooth surface, easy to clean. The powder pulverizer has changed the phenomenon that the inner wall of ordinary mill is rough, easy to accumulate powder and difficult to clean. The pulverizer machine makes food, medicine, chemical production more in line with national standards, to meet the GMP health requirements.

Powder Pulverizer Advantage:

1. Room temperature: The pulverizer has the function of self-cooling, and the main engine does not heat up

2. Controllable: no stop, you can adjust the fineness of discharge

3. Range: Suitable for crushing with 120-400 mesh fineness

4. Loss: The filter recovery rate of the pulverizer machine is 99.8%, less clean dust

5. Productivity: vertical axis reflection type ultrafine grinding cavity, higher efficiency

6. Low cost: almost no wearing parts, low production cost

Powder Pulverizer Video:

Technical Parameters:

| Model | Main Structural Dimensions(mm) | Capacity | Input Particle Size |

Output Particle Size |

Speed | Machine weight |

Total power |

||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| L1 | L2 | H1 | H2 | H3 | H4 | W1 | Kg/h | mm | mesh | rpm | Kg | KW | |

| MR-15 | 3950 | – | 2640 | 850 | 650 | 350 | 1450 | 10-150 | 6 | 60-320 | 6000 | 1100 | 13.5 |

| MR-20 | 4300 | 5900 | 2800 | 850 | 650 | 350 | 1450 | 15-200 | 10 | 60-320 | 5400 | 1400 | 21 |

| MR-30 | 5250 | 7050 | 3200 | 950 | 650 | 350 | 1550 | 50-600 | 12 | 60-320 | 3800 | 2300 | 46 |

| MR-60 | 6100 | 8100 | 3700 | 1050 | 650 | 400 | 2000 | 100-1000 | 15 | 60-320 | 2900 | 3800 | 84 |

| MR-80 | 7200 | 9200 | 4250 | 1150 | 650 | 400 | 2300 | 120-1500 | 15 | 60-320 | 2500 | 5100 | 123 |

| MR-100 | 7900 | 10100 | 4500 | 1250 | 650 | 400 | 2500 | 150-2000 | 20 | 60-320 | 2000 | 7400 | 183 |

| Our company can be customized according to the user’s special requirements. | |||||||||||||